This project has been outsourced to WERL by a Toronto-based company that is currently developing innovative pico-scale hydro turbine systems, used for energy harvesting in both water disinfection and pressure regulation applications.

This project has been outsourced to WERL by a Toronto-based company that is currently developing innovative pico-scale hydro turbine systems, used for energy harvesting in both water disinfection and pressure regulation applications.

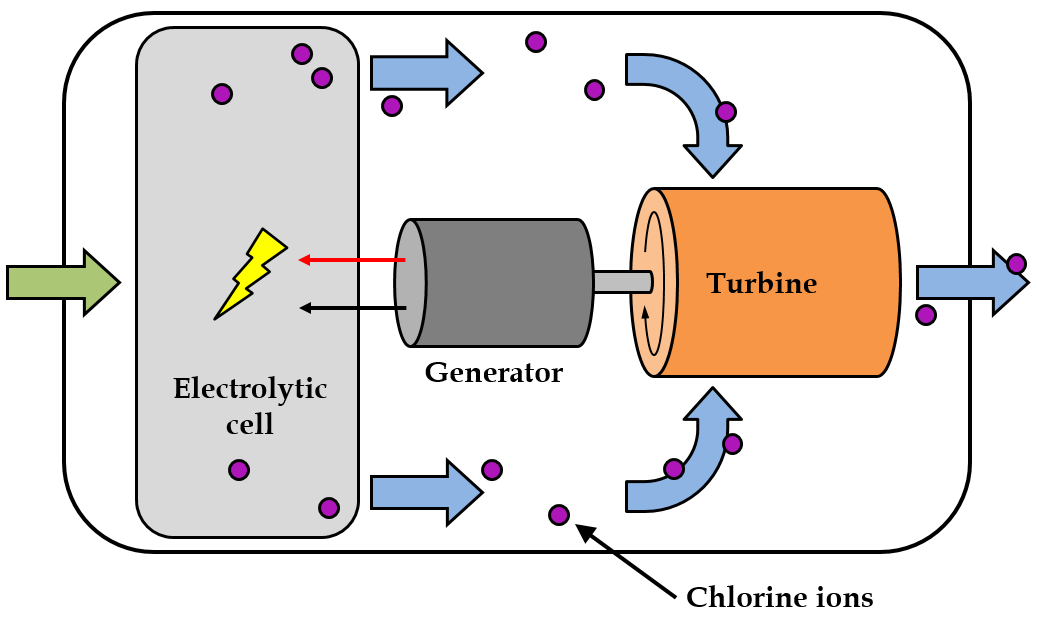

In the disinfection system, a generator coupled to the pico-turbine provides power to an electrochemical cell appropriate for drinking water disinfection. The system is self-contained, with the water for disinfection also providing power. This makes the system suitable for directly disinfecting water sources with a natural head (rivers and artesian wells). Water stored at an elevation may also be disinfected as it is drained for use.

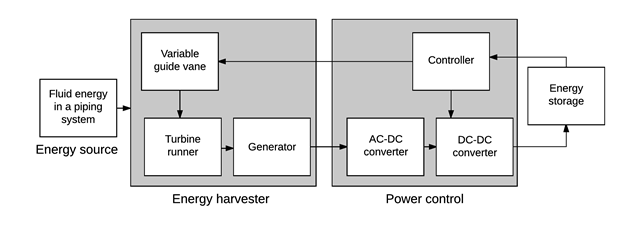

Energy is lost in hydraulic piping networks to step down the upstream pressure, which can be recovered by a replacement with an energy harvesting system. The energy harvester utilizes a pico-scale hydro turbine to extract the energy that would otherwise be wasted. The energy can then be stored in a battery to power local sensors and actuators in the system.

Challenges

Some key challenges exist for the design of pico-scale turbines. There are very few pico-hydro systems reported to operate within the ranges necessary to provide power for these applications and little published research on design techniques for turbines

at this scale. Furthermore, in order to be effective for energy harvesting, these turbines must operate efficiently across a wide range of flow conditions. The guide vane mechanism that is designed to adjust according to various flow conditions will need to be assembled into a small form factor, while being robust enough to operate in high inlet pressures.

Research Objectives

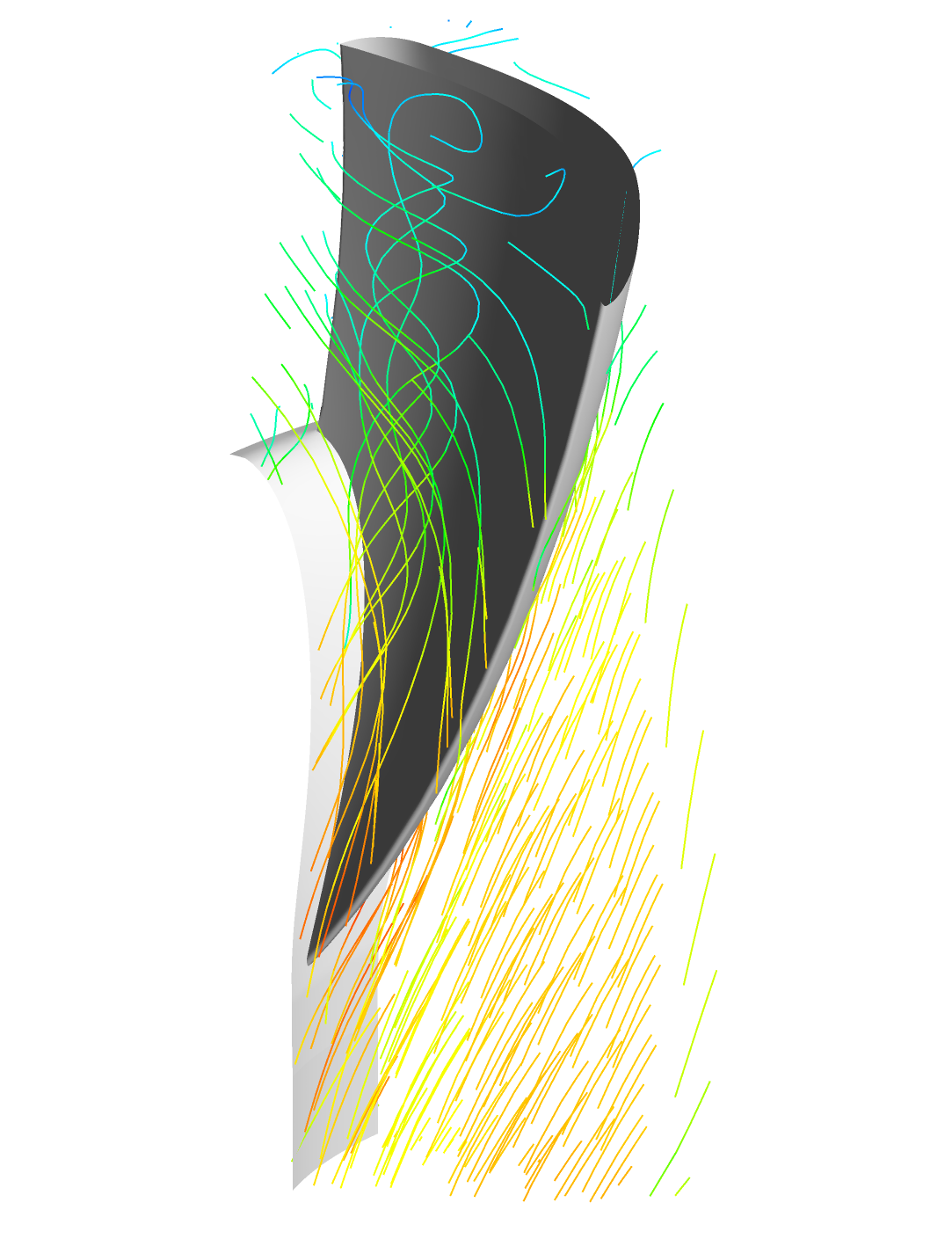

- Develop a computational fluid dynamics (CFD) model of the turbine, coupled to a mathematical model of the generator-turbine system. Implement an iterative multi-objective optimization scheme to develop turbine geometries with improved performance across a range of operating points. Optimize the disinfection system’s turbine, validating the predicted improvement with bench testing of the system.

- Provide initial optimized geometries of the runner and the guide vanes of the energy harvester with pressure drop models and CFD simulations. Forward the prototyping phase onto a working demonstration with variable guide vane position through its control system and mechanism to regulate downstream pressure at various inlet condition.